Description

Wat is een HDPE plaat?

HDPE staat voor High Density Polyethylene, ofwel polyethyleen met een hoge dichtheid (PE-HD). Deze kunststof platen worden veel gebruikt in sectoren als de apparatenbouw, chemische industrie, voedingsmiddelenverwerking en transport. Een HDPE plaat combineert een lage kostprijs met uitstekende technische eigenschappen, zoals slijtvastheid en chemische bestandheid. Omdat HDPE geen vocht opneemt en makkelijk te reinigen is, wordt het vaak toegepast in omgevingen waar hygiëne belangrijk is. Daarnaast is het materiaal smaak- en reukloos, waardoor het geschikt is voor direct contact met voeding- en levensmiddelen. Polyethyleen is daarmee het meest toepasbare kunststof in de industrie.

Opbouw van HDPE kunststof

HDPE sheets worden gemaakt van koolstof- en waterstofmoleculen. Tijdens het productieproces worden deze moleculen met behulp van een katalysator verbonden tot lange ketens. Hierdoor ontstaat een semi-kristallijne kunststof met een hoge dichtheid. De nieuwste generatie HDPE, PE100-RC, heeft nog betere prestaties en is geschikt voor veeleisende toepassingen, zoals drukleidingen en tankbouw.

Voordelen van HDPE kunststof

Waarom zou u kiezen voor HDPE platen? De voordelen op een rij:

- Zeer slag- en stootvast, ook bij lage temperaturen

- Excellent chemical resistance

- Geschikt voor contact met voedsel

- Lage vochtopname

- Goede elektrische isolator

- Eenvoudig te verwerken: zagen, lassen, buigen

- Lightweight

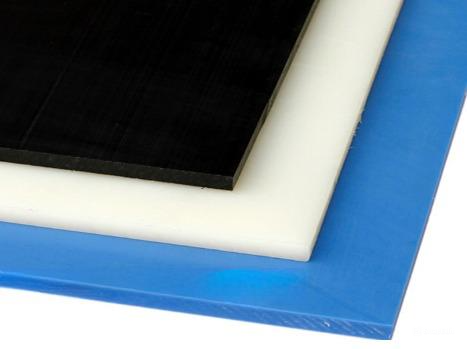

- Verkrijgbaar in zwart en andere kleuren

Toepassing van HDPE platen

Door de combinatie van chemische bestendigheid, hygiëne en slijtvastheid is HDPE een van de meest toegepaste kunststoffen in de industrie. HDPE kunststof wordt in tal van sectoren gebruikt, waaronder de tank- en apparatenbouw, transport en laadbak constructies, geluiddempende panelen, speeltoestellen, glijbanen en snijplanken. Maar ook in orthopedische toepassingen is het een populaire materiaalkeuze, evenals in de vis- en vleesverwerkende industrie.

Vooral platen van HMPE 500 worden veel toegepast als snijplaten voor vlees en vis. Het kunststof is bovendien zeer goed bestand tegen chemicaliën. Ook is dit materiaal zeer geschikt voor het bouwen van afzuiginstallaties voor walbeschoeiing, stortkokers, containers en chemische apparaten.

Processing options

Een HDPE plaat is op verschillende manieren te bewerken. HDPE lassen is goed mogelijk, vooral bij typen als PE250. Hechting met lijm lukt meestal niet, vanwege het vettige oppervlak. Daarom adviseren we mechanische bevestiging met schroeven of bouten. Let wel op de thermische uitzetting van het materiaal. HDPE zet bij temperatuurverschillen relatief sterk uit. Mogelijke bewerkingsmethoden zijn:

- Lassen (warmtelastechniek)

- Verspanen (frezen, zagen)

- Thermisch vormen en buigen

- Waterstraal- en lasersnijden

Waar moet u op letten bij het kopen van HDPE?

Omdat HDPE een relatief zachte kunststof is en doorgaans zonder beschermfolie geleverd wordt, kunnen lichte oppervlakkige krassen voorkomen. Dat maakt het minder geschikt voor zichtwerk- of presentatie-toepassingen. Zoekt u een kunststof met een hoogwaardige visuele afwerking? Dan is acrylaat of Plexiglaseen beter alternatief. Voor technische toepassingen is HDPE echter een uitstekende keuze.

HDPE plaat op maat bij Kunststof Forte

Bent u op zoek naar een HDPE plaat op maat? De zwarte HDPE platen van Kunststof Forte zijn op maat te bestellen, in diverse afmetingen en diktes. U kiest eenvoudig de gewenste specificaties in onze webshop. Bijvoorbeeld een plaat van 10 mm dik, 1000 mm breed en 2000 mm lang. Heeft u een specifieke toepassing? Neem dan gerust contact met ons op. We voorzien u graag van persoonlijk advies en denken met u mee over de juiste HDPE variant en afmetingen.

HDPE plaat kopen?

Wilt u een plaat van HDPE kopen? Bestel deze eenvoudig via de webshop van Kunststof Forte. U kiest zelf de gewenste maat, en wij zorgen voor een snelle levering. Heeft u vragen over HDPE materiaal, toepassingen of bewerkingen? Vraag een offer aan of neem contact met ons op door te mailen naar info@kunststofforte.nl or call us on +31 (0) 622 340 847. We helpen u graag verder met deskundig advies.